One of the principal reasons that I publish this blog is to encourage you to have faith that an alternative future is possible. We do not have to accept the status quo.

With faith you can join me and others in advocating and voting for a future free of fossil fuels. Rather than accepting the propaganda that intrenched industries spew out, you will be armed with knowledge and information that will help inform your thinking.

In this vein, I am often told that it is a pipe dream to believe my vision that by 2025 virtually all mass market cars and light duty trucks will run on electricity. I’m told that challenges of size, weight, cost, range and long charging times of the batteries present insurmountable challenges.

But I have faith that these issues are being solved step by step and that sooner, rather than later, they will all be resolved. Even now, GM and Tesla are preparing a vehicle that will soon be available for a price in the mid $30’s range that will go 200 miles or more on a single charge.

And now, this breakthrough. If proven out at scale, it will have an enormous impact.

Read on and have faith. We can and will do this…

Scientists solve nagging problem with lithium-ion battery material

Umair Irfan, E&E reporter

Monday, March 9, 2015

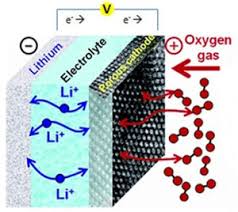

In developing better rechargeable batteries, engineers have long sought to use an anode made of pure lithium metal.

The material has 10 times the energy density of graphite impregnated with lithium ions, the most common anode material in conventional lithium cells. This is a critical advantage for applications like electric cars, where space and weight are major constraints.

However, lithium metal has a tendency to form dendrites in a cell. Dendrites are metallic projections that branch out from the surface of the anode over time. They lower the performance of the cell and eventually get long enough to pierce the membrane separating the cathode from the anode, creating a short circuit.

Researchers at the Pacific Northwest National Laboratory recently found a way to prevent dendrites. They published their findings last month in the journal Nature Communications.

The solution was to use an electrolyte with concentrated salts, according to Jiguang Zhang, a co-author and chief scientist in battery technology in the Energy & Efficiency Division at PNNL.

Zhang explained in an email that dendrites form when there is an uneven supply of lithium ions at the interface where the anode meets the electrolyte, leading lithium metal to concentrate in certain areas instead of distributing evenly.

‘A drop-in replacement’

Another factor is the solid electrolyte interface, a structure than forms inside a cell when the electrolyte breaks down (ClimateWire, March 11, 2014). If the structure is weak, dendrites will push through.

“Our new electrolyte addressed these two fundamental problems at the same time,” Zhang said.

The high salt concentration in the electrolyte forced the lithium ions to spread out evenly, preventing them from clumping and forming metal peaks. The electrolyte itself breaks down into a solid electrolyte interface that is mechanically stronger than in a conventional cell, coating the anode and further preventing dendrite growth.

“The new electrolyte completely changed the growth pattern of lithium metal from a needle-like structure (which can penetrate the battery separator and lead to safety problems) to a large, round shaped nodule-like structure that cannot penetrate battery separator and therefore can avoid the safety problems related to dendrites,” Zhang said.

Putting this into a working cell would likely be straightforward. “This is a drop-in replacement,” he added. “All the battery manufacturing processes and cell structures do not need to be changed. The only change needed is the formulation of the electrolyte which will be added into the cell at the last step of battery preparation.”

Kang Xu, a chemist at the U.S. Army Research Laboratory who was not involved in this study, said the findings are a step toward making lithium a viable anode material. “These are real significant, fundamental breakthroughs to have control over how [dendrites] grow,” he said.

However, he cautioned that such work is still an exploration of fundamental science and that engineers must test the electrolytes in an actual cell to make sure it plays nice with other components. “We don’t know how the electrolyte will handle the cathode side,” he said.

Twitter: @umairfan | Email: uirfan@eenews.net