I am trying something a little different today. I want to see if this is an improvement from what I have done in the past. Let me know what you think after you’ve had a chance to check it out. Email me back with a thumbs up or down, yes or no, or some such indicator. I am going to go into some depth on a single article as usual. But before doing that I am going to display a couple of recent headlines and maybe a brief description of the article in order to keep you abreast of current developments.

The following was published this past week or so relating to changing weather and its impact.

Fisheries Disasters Jump with Warming. But Feds Fail to Act

Friday, May 7, 2021

“extreme environmental events such as hurricanes, marine heat waves and harmful algal blooms caused 95% of the disaster damage to fisheries from 2014 to 2019. From 1994 through 1998, environmental events caused just 38.5% of the disaster damage to fisheries.

“Environmentally driven fishery disasters are clearly on the rise, fueled by extreme environmental events that occur as symptoms of a changing climate,””

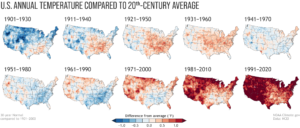

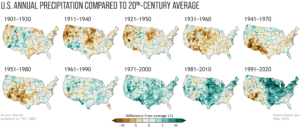

Climate Change and the 1991-2020 U.S. Climate Normals

Rebecca Lindsey

April 19, 2021

In case you’ve still have any doubt about whether the weather is changing…While these two charts may be a little hard to read and interpret, the colors speak for themselves. They show the dramatic increase and change in the last hundred years of heat and precipitation. If you’ve been thinking that the weather is not what it used to be when I was a kid, you are correct. And this is only beginning!

On to this week’s featured article. Back to the transformation of the auto industry from ICEs (internal combustion engines) to electric vehicles (EVs).

I have been consistently saying that the current (pun intended) battery technology will evolve from lithium ion technology to something cheaper, lighter, smaller and more energy dense. This will lead to a vastly more attractive vehicle being less expensive with a greatly improved range and more roomy interiors. This article describes progress in this evolution.

“sulfide solid-state battery technology…should give Ford the flexibility to either shrink battery sizes to make it less expensive to manufacture some vehicles or keep the same size battery and achieve a greater range of distance in other models.”

“much higher levels of energy density. For customers, that basically means they can drive farther with the more range. So as you get better energy and power density, the cells get smaller. That allows the vehicles to become lighter for the same range, as well as more space for people and their things instead of for batteries. And then, of course, cost. Being able to drive the cost per kilowatt-hour down will speed up the adoption of battery electric vehicles.”

Maybe this will work and be the future. But if not this, then one of the other alternatives will prevail. In any case, something better is bound to be proved out and that will accelerate (yes, pun intended again!) the rapid adaptation of EVs.

Ford is Betting that Solid-State Batteries will Cut Costs

May 6, 2021

Ford Motor Co. has raised its stake in a manufacturer of solid-state batteries — a move that its chief product and operations officer, Hau Thai-Tang, says will strengthen the company’s effort to increase the range and reduce the costs of its next generation of electric vehicles.

Ford, along with BMW, this week announced their investment in a $130 million funding round for Solid Power, a Denver-area company that is developing sulfide solid-state battery technology. Thai-Tang says the technology should give Ford the flexibility to either shrink battery sizes to make it less expensive to manufacture some vehicles or keep the same size battery and achieve a greater range of distance in other models.

Solid-state batteries, with their solid ion-conducting material instead of the liquid electrolyte found in most lithium-ion batteries, can store more energy. This expands the vehicles’ range from the same-size battery or allows for smaller batteries, which are typically lighter with a lower risk of fire.

At the same time, it’s harder to draw power from solid-state batteries than from lithium-ion batteries, said Sam Abuelsamid, an analyst at Guidehouse Research. But the technology holds such promise, he said, that whatever company perfects it first could command a competitive edge.

The Associated Press spoke recently with Thai-Tang about the new chemistry and what it could mean to speeding the adoption of electric vehicles. The interview was edited for clarity and length.

Why are solid-state batteries so important compared with the lithium-ion batteries now used in electric vehicles?

Because of the promise of much higher levels of energy density. For customers, that basically means they can drive farther with the more range. So as you get better energy and power density, the cells get smaller. That allows the vehicles to become lighter for the same range, as well as more space for people and their things instead of for batteries. And then, of course, cost. Being able to drive the cost per kilowatt-hour down will speed up the adoption of battery electric vehicles.

What’s the advantage over lithium-ion batteries now?

The big thing is going from a liquid electrolyte to a solid electrolyte; that gives you better conductivity. That’s the enabler for the power and energy. The challenge has always been, can you actually scale it up to where the format of the cell is large enough for automotive use? Then can you actually manufacture it at scale to hit the cost targets?

There has been a lot of talk about potential shortages of lithium, copper, nickel, other precious metals. Does solid state use fewer of those?

It depends on the chemistry. For most companies, the cathode is about the same as what’s in lithium-ion. That doesn’t really change. It’s really the anode and the electrolyte. Because you’re getting higher conductivity and higher energy density, so for the same power and range and energy, you would use less. That in itself will help, even if it was the same chemistry. But depending on which company you partner with, they would have different chemistries, which will reduce dependencies on things like copper as well as cobalt, for example.

How far along is Solid Power in this process?

We think Solid Power is among the leaders because of their ability to scale up to a multilayer cell, up to 20 amp-hour. This is something that we can actually use in an automobile. Beginning next year, they’re targeting to give us as well as the other investor, BMW, a 100 amp-hour battery. That’s at the size we really can use for automotive applications. The other big thing is, their chemistry can be built in the same manufacturing process that we would invest in to build lithium-ion batteries. So this allows us to ease into that new technology without having to reinvest in all of that capital equipment.

What time frame do you see for switching to solid-state?

We think it’s realistic to target by the end of this decade if we continue to make the progress we’re making.

Does this announcement mean there will be a much wider array of electric vehicles coming?

Ford can lead the electric revolution and accelerate the transition from internal combustion engines to drive the cost down and improve the range for our customers, making it safer. I think charging infrastructure is probably the other thing that would be the key for a faster rate of adoption. — Tom Krisher, Associated Press