In the past I have written about potential pivotal technology advances that will change the paradigm for electric vehicles (including planes and ships). We have all read many announcements with hope, only to never see these come into commercial fruition. (Although in an upcoming post I am going to be following up on one that I wrote about not too long ago that actually IS going into full scale adoption!) But, when IBM “speaks”, you’ve got to listen.

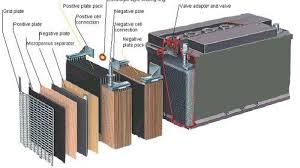

As I have said all along, lithium ion batteries are not going to be the ultimate technology that will drive the full scale conversion to fully electric vehicles for a variety of reasons such as cost, size and weight, charging speed and component sourcing issues. So now… a solution.

“IBM is developing a safer, more powerful electric battery that promises to reduce the charging time for electric vehicles and may enhance the possibility of electric aircraft, the company announced yesterday.”

“Because the battery would be able to store more power, Allen predicted that EV owners could fast-charge the battery, giving it 80% of its power within five minutes.”

“The introduction of new materials also allowed IBM researchers to eliminate two heavy metals, nickel and cobalt, from the battery’s formula, reducing its cost and expense. There is no mining associated with iodine, Allen noted, because it can be extracted from seawater.

“We think of this now as not just a research project; we are really focused on pivoting to production,” explained Allen, who said it led IBM to develop a consortium of companies that could help produce the upgraded battery in two to three years.”

Here we go!!

IBM Announces Battery Breakthrough

Thursday, December 19, 2019

IBM is developing a safer, more powerful electric battery that promises to reduce the charging time for electric vehicles and may enhance the possibility of electric aircraft, the company announced yesterday. In an interview, Bob Allen, senior manager of materials innovation at IBM’s Almaden laboratory in San Jose, Calif., said the breakthrough came with the addition of iodine to the lithium-ion battery’s chemistry. Two years ago, the change startled researchers with “just extreme, out-of-the-chute power density,” he said.

The introduction of new materials also allowed IBM researchers to eliminate two heavy metals, nickel and cobalt, from the battery’s formula, reducing its cost and expense. There is no mining associated with iodine, Allen noted, because it can be extracted from seawater.

“We think of this now as not just a research project; we are really focused on pivoting to production,” explained Allen, who said it led IBM to develop a consortium of companies that could help produce the upgraded battery in two to three years.

The group includes Mercedes-Benz Research and Development North America, which is developing electric cars, and Central Glass Co. Ltd., a Japanese company that is a major manufacturer of battery electrolyte, a substance that produces an electrically conducting solution when dissolved in water. Sidus, a Silicon Valley company, will manufacture the new battery.

Because the battery would be able to store more power, Allen predicted that EV owners could fast-charge the battery, giving it 80% of its power within five minutes. That’s about how long it takes to fill up a gasoline-powered car.

In a statement released yesterday, IBM claims that when its battery is “optimized” for use in aircraft, it will outperform “the most powerful lithium-ion batteries available.” Currently, there are no cost-competitive, low-carbon fuels or engines that can propel passenger planes.

The company also said its proposed battery has a relatively low flammability, which would give larger versions of the battery a safety factor that could help utilities store more electricity from solar and wind farms. Over the last two years, South Korean utilities have experienced 23 lithium-ion battery fires.

In April, there was a fire and explosion at a battery facility connected to a utility’s solar power array west of Phoenix. It sent a policeman and several firemen to local hospitals. Investigators in the United States and South Korea have not isolated a single cause for the battery fires.

Research into IBM’s battery chemistry was helped by an “atomic force microscope” that enabled scientists to examine the battery’s operation at the molecular level. “What we have is a battery that looks incredibly compelling that has a lot of interesting attributes,” said Allen.

According to the IBM statement, the new battery stems from the development of “three new and different proprietary materials,” which do not appear to have been used in previous batteries. It also noted that cobalt, used in current batteries, has a “sourcing concern” because it is found in central Africa, where some companies use child labor to manually dig it out of the ground.

Previously, IBM’s Almaden laboratory pioneered a process to make integrated circuits, which is now used worldwide.